Tensile strength is one of the most important mechanical properties of steel, as it defines how much pulling or stretching force the material can withstand before breaking. For industries such as construction, automotive, aerospace, and manufacturing, understanding the tensile strength of steel is essential to selecting the right grade of steel for structural integrity and performance.

What Is Tensile Strength?

Steel tensile strength refers to the maximum amount of tensile (pulling) stress that a material can endure without fracturing. It is usually measured in pounds per square inch (psi) or megapascals (MPa). When steel is subjected to tension, it first experiences elastic deformation (where it can return to its original shape), followed by plastic deformation (permanent stretching), and finally failure at the point of fracture. The tensile strength is the peak stress recorded just before the steel breaks.

Typical Tensile Strength of Steel

Steel is an alloy primarily composed of iron and carbon, but different grades of steel vary in composition and processing, leading to a wide range of tensile strength steel values:

-

Low Carbon Steel (Mild Steel):

Tensile strength typically ranges from 400–550 MPa (58,000–80,000 psi). Mild steels are ductile and easily machinable, making them suitable for applications like sheet metal, pipes, and automotive panels. -

Medium Carbon Steel:

With tensile strength between 550–700 MPa (80,000–100,000 psi), this steel offers a balance of ductility and strength. It is often used in machine parts, axles, and gears. -

High Carbon Steel:

Tensile strength can reach 700–1,000 MPa (100,000–145,000 psi) or higher. High carbon steel is stronger but less ductile, making it useful in applications like cutting tools, springs, and high-strength wires. -

Alloy Steels and Stainless Steels:

Depending on alloying elements and heat treatment, tensile strength can range from 500 MPa to over 2,000 MPa (72,000–290,000 psi). For example, martensitic stainless steels and quenched alloy steels can achieve extremely high strength while maintaining corrosion resistance or toughness.

Factors Affecting Tensile Strength

Several factors influence the tensile yield strength of steel, including:

-

Carbon Content: Higher carbon increases strength but reduces ductility.

-

Alloying Elements: Elements like chromium, nickel, vanadium, and molybdenum enhance strength, toughness, and resistance to wear.

-

Heat Treatment: Processes like quenching, tempering, and annealing significantly affect tensile properties.

-

Manufacturing Method: Rolled, forged, or cast steels may have different tensile strengths due to grain structure and internal defects.

Testing Tensile Strength

The tensile strength of steel is determined using a tensile test, where a standardized specimen is pulled in a universal testing machine until it fractures. Stress-strain curves obtained from these tests show the yield strength, tensile strength, and elongation at break, which provide valuable insights into the mechanical behavior of the steel.

Importance in Industry

Steel tensile strength is a critical property for safety and performance in engineering applications. In construction, it ensures steel beams can carry heavy loads without failure. In automotive design, it helps in creating lightweight yet strong structures for fuel efficiency and crash resistance. In aerospace, it guarantees that steel components withstand extreme stresses without failure.

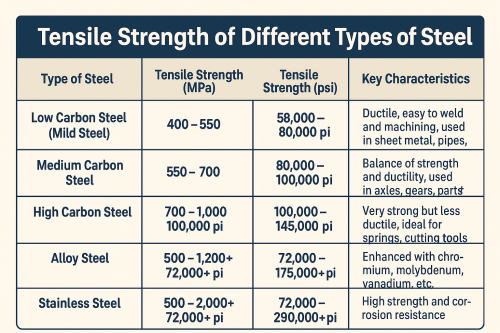

Tensile Strength of Different Types of Steel

| Type of Steel | Tensile Strength (MPa) | Tensile Strength (psi) | Key Characteristics |

|---|---|---|---|

| Low Carbon Steel (Mild Steel) | 400 – 550 MPa | 58,000 – 80,000 psi | Ductile, easy to weld and machine, used in sheet metal, pipes, and automotive panels. |

| Medium Carbon Steel | 550 – 700 MPa | 80,000 – 100,000 psi | Balance of strength and ductility, used in axles, gears, and machinery parts. |

| High Carbon Steel | 700 – 1,000 MPa | 100,000 – 145,000 psi | Very strong but less ductile, ideal for springs, cutting tools, and wires. |

| Alloy Steel | 500 – 1,200+ MPa | 72,000 – 175,000+ psi | Enhanced with chromium, molybdenum, vanadium, etc. for toughness and wear resistance. |

| Stainless Steel | 500 – 2,000+ MPa | 72,000 – 290,000+ psi | High strength and corrosion resistance, used in construction, medical, and aerospace. |